This web page describes the Max Gray SP 2-6-0 upgrade project.

The MG SP 2-6-0 is one of my favorite prototypes and models. Years ago I worked a few miles from Max Gray's shop in Santa Clara, CA. I went there to buy an HO scale SP MT-4 for a Christmas present for my Dad. When I walked in the door my eyes immediately went to the O scale SP 2-6-0 sitting on a display shelf. The SP 2-6-0 loco is to me the epitome of small capable SP steam - headlight location, cylinders, dome shapes and locations, and the Vanderbilt tender. I have owned and sold two, the second of which was upgraded by me. I now have a third that I will use to prototype changes for this project that were not made when I upgraded the second model.

A brief note about the model. Max Gray's literature described it as a "1700 Series SP 2-6-0." The 1700s 2-6-0s were SP's class M-6. However, there are a couple of anomalies when comparing the model to M-6 class 2-6-0s. The cross head guide hangar is that of the M-9 class - I have studied every SP 2-6-0 photo that came in front of me, and I find that only the 1800 series M-9 2-6-0s have the curved outside crosshead guide hangar. Baldwin built the M-6 and M-8 classes, while the M-9 class was built by Brooks, so that would explain the different hangar. The other anomaly is that the sand box appears to be the M-6 sand box, not the M-9's box. Now it is possible that one M-6 was rebuilt with the curved crosshead guides and that Max Gray chose to model that loco for his import and that the only photo was not returned by the Japanese builder; stranger things have happened. What to do? It's your model so you can letter it for either class and make a good argument for accuracy. I will give you the option of making either M-8 or M-9 specific changes, see the options below.

In addition to attractive appearance they are very solid and rugged models, ideal small steam for a layout. Over time modeling methodology has changed to the point where the basic model can be improved in several ways. The upgrade project I plan is to improve the operation of the model along with changing the wheels to have a better appearance. No other cosmetic changes are proposed.

The goal of the project is to provide the customer with a loco that is ruggedly constructed, is operationally reliable and useful, and that has its realistic appearance enhanced. To accomplish this goal I will make a basic set of modifications. There are options beyond the basic modifications for the wheel profiles you desire.

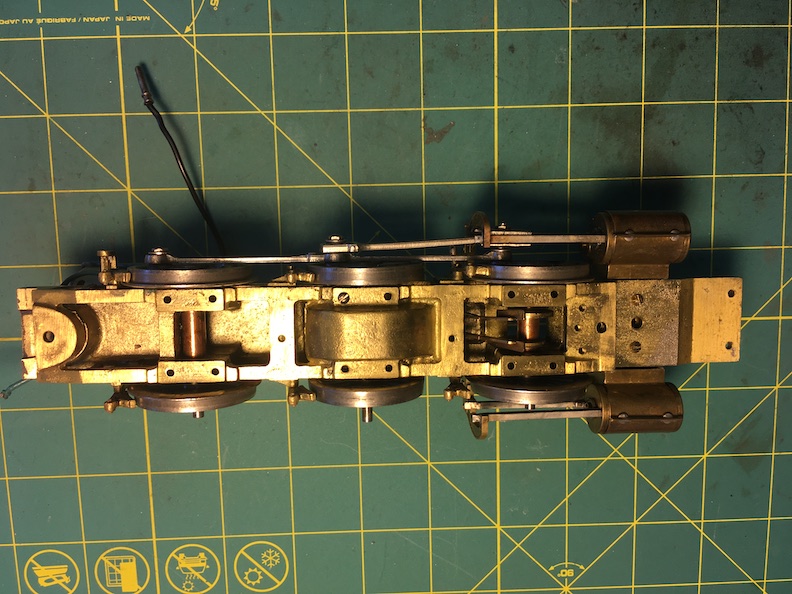

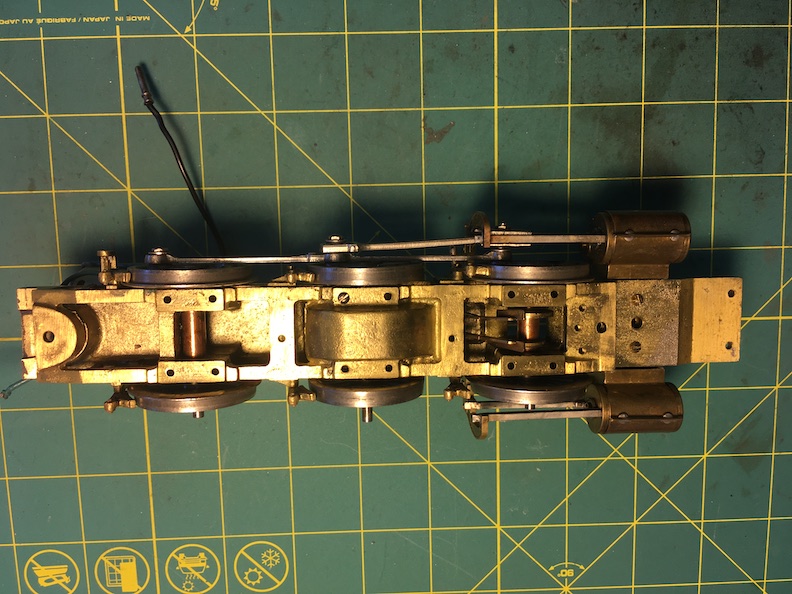

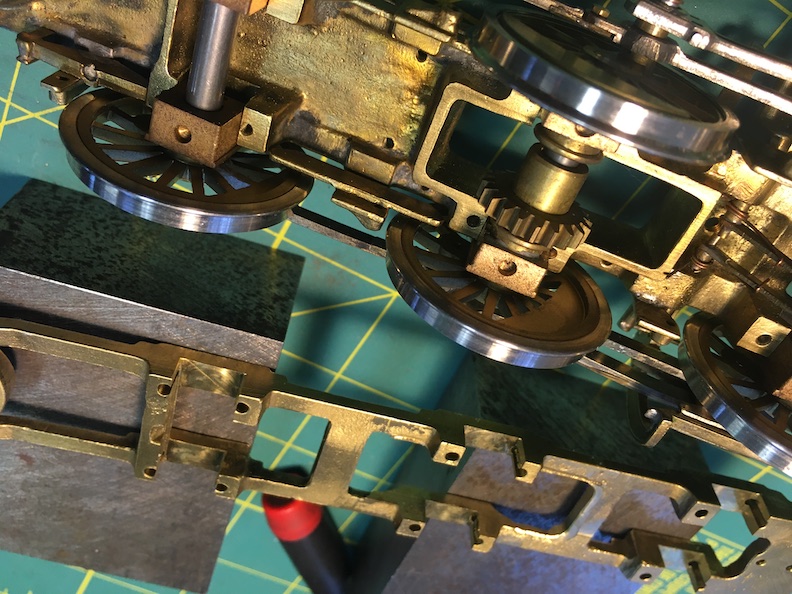

Below is a view of the underframe before modifications.

Note that the center drivers on this model have been modified. The owner of this and the below model provided them to me before I established the below ground rules, so in the after image drivers provided by the owner are shown. No other models with owner provided parts will be accepted into the project because of the work required to accommodate those parts whose size, Murphy having his way, will usually differ from the parts around which I have designed my process.

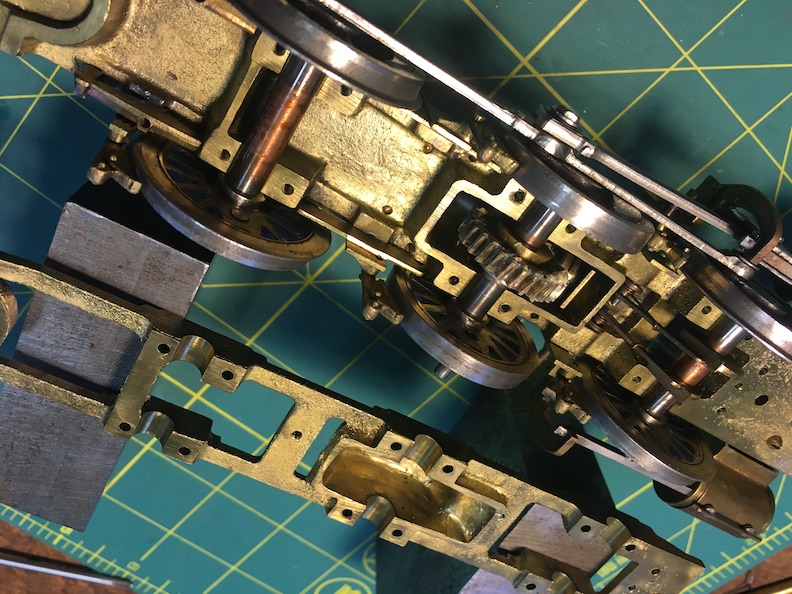

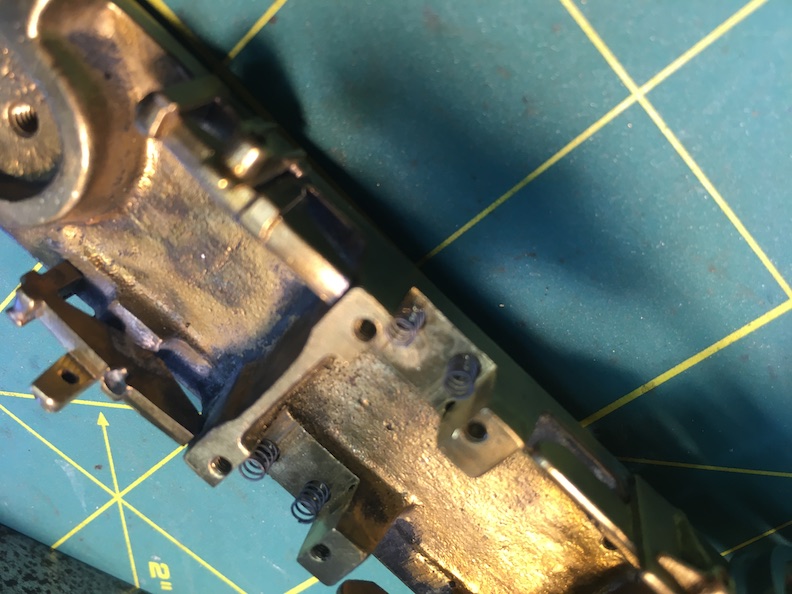

Below is a view of the frame halves before modification; the half with the drivers is the top half.

And after. See the comments above the "before" image above. Note the screws in the side rods behind the center driver crankpins that indicate the location of the rod joint. You can see the overlap of the side rod parts on the lower rod.

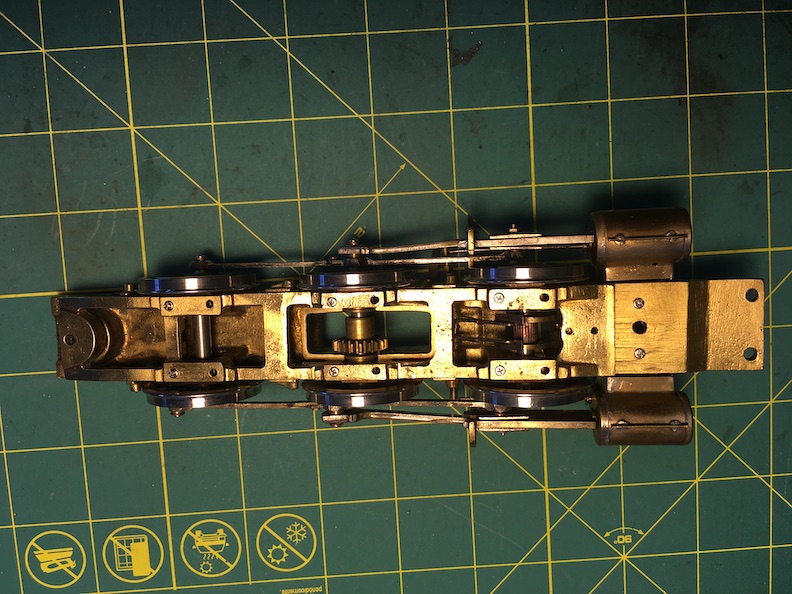

Below is a view of the frame halves after modification.

Below is a vew of the top frame half with the wheelsets removed which exposes the driver axle springs.

A Canon or 18MM square can (customer's choice) motor will be installed and connected to the gearbox. The option of a Pittman motor has been dropped because of their cost and availability.

After the project was announced I received and tested some 18MM square can motors originally made in China for remote controlled auto mirrors. The motors use Neodymium magnets and are very powerful and have good durability. I will put this motor in the personal loco that I will modify before modifying customer locos. I have good pulling power results from installing two of them in a Red Caboose GP-9 and expect the result in the mogul will also be satisfactory.

After the motor has been installed the amount and location of addtional weight so the engine balances at the center axle is determined.

With the weight of the engine known including the added weight for balancing, driver springs can be sourced or fabricated if needed, so that the engine "floats" on the springs when it is on the rails.

Contact wipers will be installed on the tender wheelset axles, connected to the engine with a plug and socket, and wired to the appropriate motor brush for reliable electrical contact.

A deck plate will be installed between the cab and tender deck. KD couplers will be installed on the pilot and rear of the tender.

The drive wheels and truck wheelsets will not be modified from their as received configuration; if they had been modified prior to my receiving the model and those modifcations create a problem I will discuss it and the possible solutions with you.

The cost for this option is estimated to be $100 including the NWSL wheelsets and the fabrication of adapter bushings.

At this writing I estimate the cost of this option to be $350 - $500 which includes the NWSL truck wheelsets along with fabricating the necessary adapters, the driver center castings, fabricating the tires and fitting them to the driver centers, and assembling the driver centers into wheelsets that are properly quartered and in gauge.

After I have completed the prototype model which will include this option I will be able to provide a better cost estimate. If the estimate is more than you want to pay, you can change your option selection or withdraw your model from the program.

At some point in time the project will be closed so that parts can be ordered. Additions to the project will not be possible after that time. A model is considered part of the project when I receive the model along with the customer's choices for the options.

I estimate the total cost for the Basic Modifications to be $700. Every loco is different, and things go bump in the night, so the actual cost may vary.

No customer provided parts. I need to provide all the parts so that I have consistent sizes and quality for batch use.

All locos that I have worked on are track tested under load on a layout, through turnouts, up grades, and are run non-stop long enough for most latent problems to emerge. The SP 2-6-0s will be verified to operate on a 48" radius curve.. If any change is made after a test run, the run is repeated to ensure no unintended consequences. You can expect the loco to run flawlessly out of the box from me.

Additional work such as DCC installation or painting is possible. It will be done by me if my workload permits, or outsourced if I can outsource that work to a competent and reliable person. Normally outsourced locos are returned to me for a repeat test and shipping to you.

Other work such as adding detail is out of the scope of this project. Other modelers who are qualified to perform this work are encouraged to let me know of their availability; I will put custom builders who respond in touch with owners wishing to have their loco detailed so the two of you can work out an agreement.

If you plan to have the loco worked on after my work is complete, I recommend that you "live with" the loco for a while so you know how it runs on your track. After the loco is returned to you I recommend that you perform an acceptance test to verify that its performance is the same as before you sent it out for other work.

I charge on a time and materials basis. I keep track of my time to the nearest 1/4 hour and add up the segments to obtain to total labor charge. Parts are charged at what I consider a fair price taking into account my cost for them. Progress billings may be made. Invoices are emailed; checks or electronic payments are accepted.

My work is guaranteed for as long as you own the model. The guarantee is void if there is inept or no maintenance, physical abuse (e.g., loco was dropped), or modifications are made to the parts I installed or modified.

Please do not hesitate to contact me if you have any questions about the above items.